Carbon reduction performance

From 2016 to 2021 Q2 shipments replaced 217,956 sets of traditional filters, helping customers create more than 1.07 billion yuan in waste reduction benefits

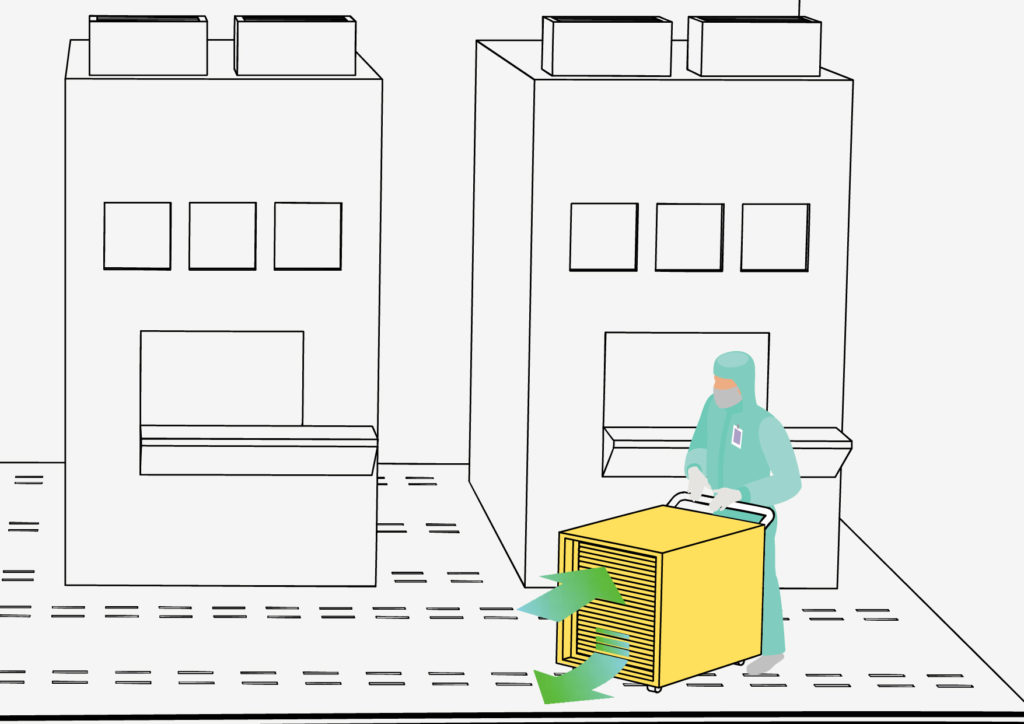

Reduce chemical filter waste

Reduce carbon emissions

Taipei 101

Daan Forest Park

GreenFILTEC Core

Filtration owns the leading technology of AMC micro-pollution control, and provides the best AMC prevention and control solutions for semiconductor and panel industry customers. Through the modular design of products, the goal of 3R is achieved (filter waste reduction/frame reuse) / filter regenerated and reused), reducing the overall purchase cost of the filter; the energy filter modular frame was awarded the second type of environmental protection label certification by the Environmental Protection Agency and the best product category of the Yushan Award, which is the first case in the industry. And passed the BS 8001:2017 circular economy assessment, and continue to propose innovative products that subvert the traditional thinking of the industry!

REDUCE

Reduce the use of single-use products

REUSE

Renewable product

REGENERATE

Reusable product

One-stop service

Site Survey & Testing

a. spatial measurement

b. parameter collection

c. Sample retrieval

Sample Testing & Analysis

a. Sample Storage and Handling

b. Instrument testing and analysis

c. Issue a test report

Program development & evaluation

a. Drafting of prevention and control standards

b. With filter specifications

c.Engineering Design Planning

Product Production & Quality Assurance

a. Filter material preparation

b. Chemical filter making

c. Filter quality inspection

Product Sales & Service

a. Filter sales and installation

b. Environmental regular inspection

c. Product recycling

Customer Opinion & Consultation

a. opinion measurement

b. data reply

c. demand confirmation

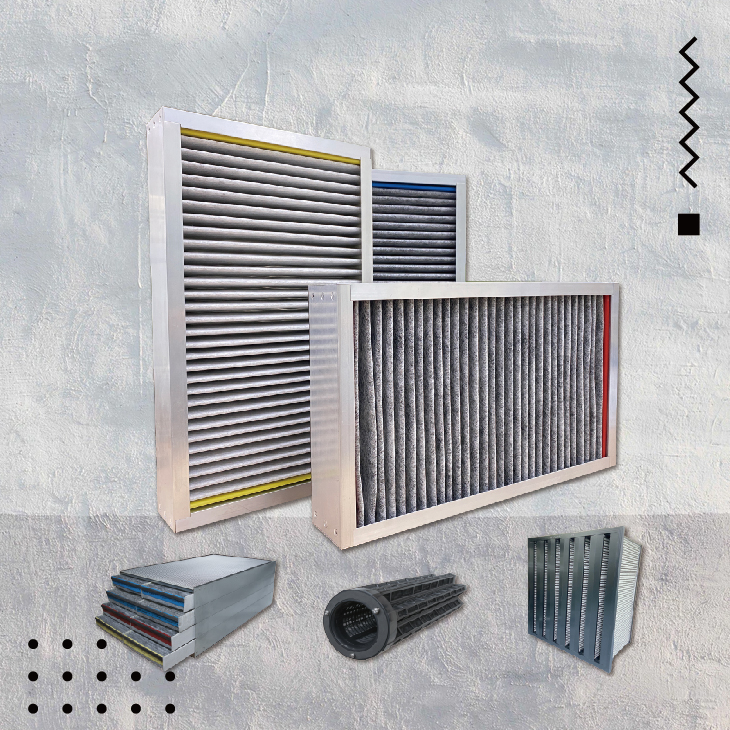

Product description

Air Filter Analysis Laboratory

AMC Total Solution

AMC analysis technology

With a professional air filter analysis laboratory team, we conduct tests for clean room environmental sampling analysis, filter efficiency, saturation capacity analysis, etc. The testable items are as follows: molecular acid (MA), molecular base (MB), condensate ( MC).

Material outgassing analysis

As precision manufacturing requires good environmental control, impurities in materials also affect the stability of finished products and application reliability. The specification of the total release amount of material impurities is particularly strict. After all, if the manufacturing equipment on the downstream customer application side is polluted and irreversible damage is caused, Filtration can provide analysis on AMC-related projects for various materials outgassing.

AMC level control

According to the information provided by customers and the results of on-site sampling and analysis by the energy filtration laboratory team, we can provide one-stop service to help customers solve various problems of AMC.

AMC total silution

According to the information provided by customers and the results of on-site sampling and analysis by the energy filtration laboratory team, we can provide one-stop service to help customers solve various problems of AMC.