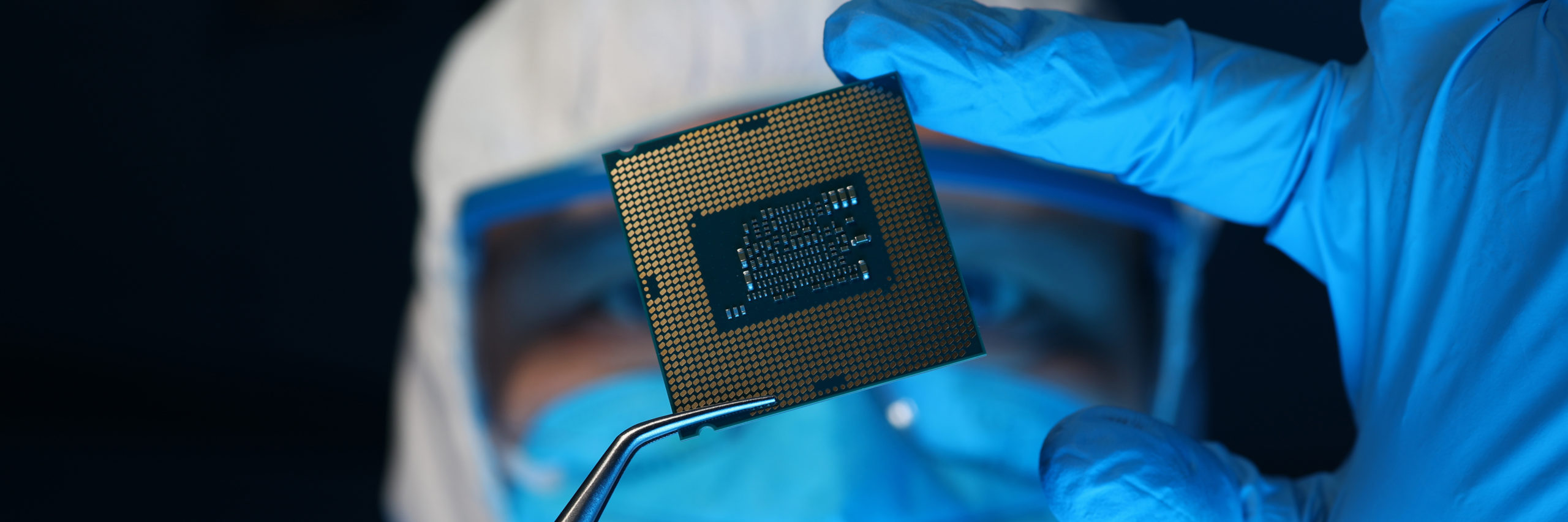

As semiconductor processes continue to evolve, the prices of wafers below 7 nanometers have skyrocketed. In order to simultaneously uphold Moore’s Law and maintain cost-effectiveness, both domestic and international major manufacturers are exploring ways to address the issue of high costs. One of the solutions can be found in the experiments conducted by GreenFiltec, a small factory located in Yangmei, Taoyuan.

Established in 2014, GreenFiltec specializes in providing services for the prevention and control of airborne molecular contamination (AMC). Through innovative research and development of filter materials, they prevent invisible gas molecules from contaminating the air, thereby avoiding the need for frequent replacement of consumables and reducing the occurrence of yield loss in cleanrooms. Their meticulous control throughout each step of the advanced manufacturing process of semiconductor wafers plays a crucial role in cost control.

In June 2021, GreenFiltec went public, and their flagship product, the “Extraction Filter,” had already captured a 50% market share in domestic advanced semiconductor processes. In 2022, they achieved over 1 billion yuan in revenue for the first time, showcasing remarkable achievements within their short 9-year history.

What is micro-pollution prevention and control, and why must advanced manufacturing processes be done?

Founder and Chairman, Huang Mingwen, holds a master’s degree in chemistry from Sun Yat-sen University, specializing in the analysis of trace instruments during his graduate studies, particularly focusing on the detection of imperceptible gas molecules in the air. After graduation, Huang joined the analysis department of TSMC (Taiwan Semiconductor Manufacturing Company), where he specialized in identifying and preventing sources of contamination in the air. He has also worked for Camfil, a prominent filter manufacturer in Sweden, throughout his career, always being involved in microcontamination prevention and control.

Describing Huang Mingwen’s entrepreneurial journey since the early days of GreenFiltec, certified public accountant Yu Zhifan, who has known Huang for a long time, mentioned that although Huang started as a small business owner from scratch, he is quite practical and not the type of dull engineer.

When asked why he was willing to leave a large corporation and venture into entrepreneurship, Huang Mingwen stated that during his career, he clearly saw a future path: “As semiconductor processes continue to evolve, cleanrooms will place even greater emphasis on contamination prevention and control. This market has the potential to explode in the future.”

In the early 2000s when Huang Mingwen joined TSMC, microcontamination prevention and control primarily focused on the yellow light area where the exposure machine was located. The exposure machine, a critical equipment that uses lens principles to transfer circuit patterns onto wafers, was susceptible to contamination due to the intense light energy, leading to the adhesion of gas contaminants on the lens and a decrease in exposure efficiency.

Once the lens absorbed excessive contaminants and became uncleanable, it had to be replaced as a whole set. This replacement process, along with the reconfiguration, typically took around two to three months. Additionally, wafers that failed the exposure process had to be discarded, impacting productivity and costs. This is why semiconductor fabs exerted great efforts to prevent microcontamination.

Huang Mingwen recalled that around 2006, as wafer manufacturing precision improved, microcontamination prevention gradually extended to comprehensive area control. He mentioned, “Later, during the back-end packaging stage, microcontamination prevention also became necessary.”

However, for many years, semiconductor fabs had been purchasing filters from foreign suppliers, with critical technologies not being domestically available. This posed significant challenges for Huang Mingwen during the early days of his entrepreneurship. Fortunately, a phone call from a major wafer fab in the middle of the night opened the door for GreenFiltec to enter the advanced manufacturing supply chain. With three strategic moves, GreenFiltec successfully secured orders from renowned domestic wafer fabs, as well as major memory manufacturers from the US and Taiwan.

GreenFiltec breaks through the gate of the fab with three tricks, and the secret technique of single-handedly challenging the big factories is disclosed

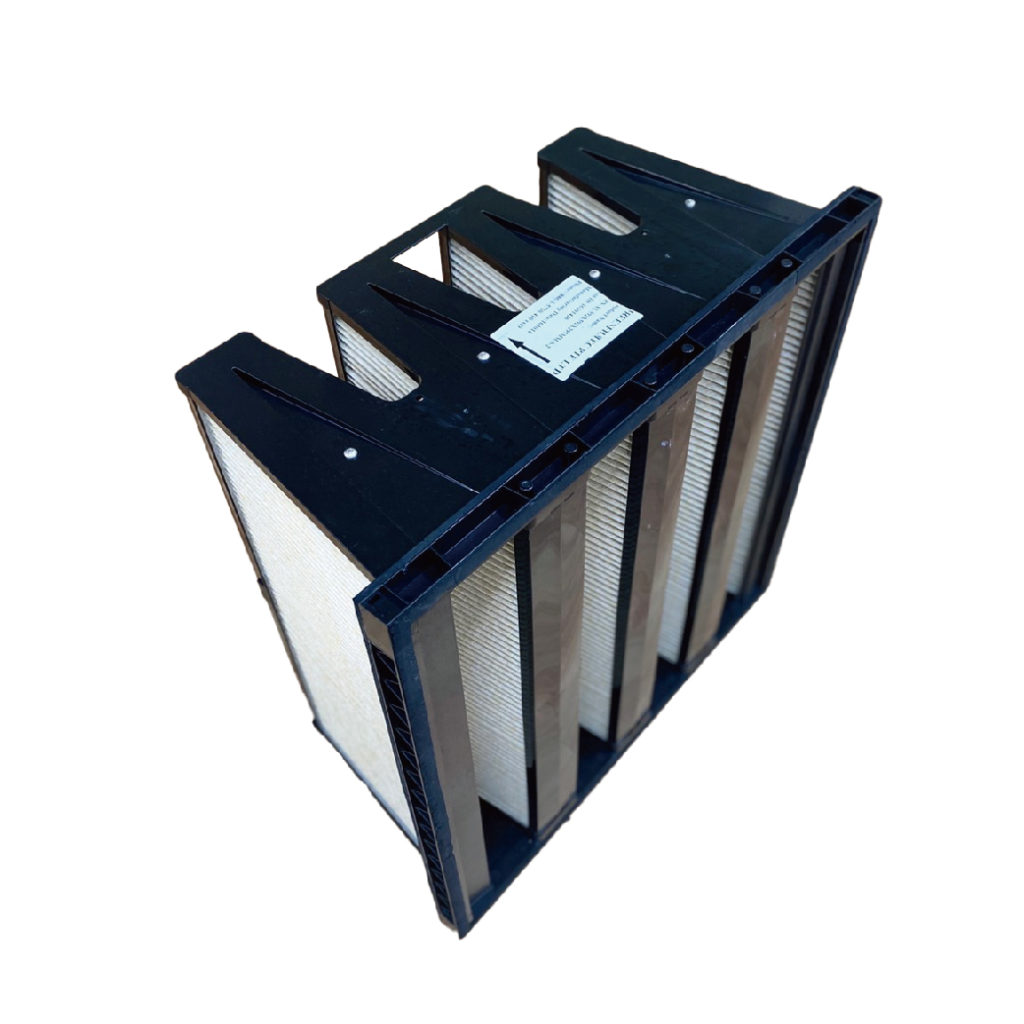

GreenFiltec’s first strategic move was the disruptive innovation of their extraction-style filter design.

Huang Mingwen recollects, “One stormy night in 2016, the wafer fab suddenly called me.” It turned out that the engineer on duty had discovered microcontamination in the fab and needed support. However, at that time, the filters in the fab were provided by foreign suppliers, and there were no on-duty personnel during the night. Furthermore, the filters were designed as integrated modules, weighing approximately 25 to 30 kilograms per set, and each replacement required 10 to 20 sets. This was an impossible task for a single equipment engineer to handle.

However, GreenFiltec adopted an extraction-style design with individual filter panels weighing less than 1 kilogram. When it was time to replace the filters, only the extractable portion needed to be removed, similar to removing a graphics card from a computer, without replacing the entire module. “The wafer fab recognized the advantages of our easily replaceable product. With one engineer able to handle ten panels, it was safer for high-altitude operations. Traditional filters would require a group of people,” Huang Mingwen explains.

The innovation lies in the concept of “airtightness,” which many filter developers highly value. Therefore, the extraction-style design posed a significant challenge fundamentally. “For those involved in filter design, it is not easy to change their mindset,” Huang Mingwen remarks. Even foreign contract manufacturers initially outright stated, “It’s impossible.”

GreenFiltec’s approach is to focus on materials and develop the most suitable filter media that meet the airtight standards of wafer fabs, aiming to achieve better microcontamination prevention and control results rather than emphasizing solely on sealing. Huang Mingwen analyzes, “Because we didn’t start as a filter manufacturer and instead entered the industry halfway, we tend to think, ‘Oh, it’s simple!'”

It was this opportunity that allowed major wafer fabs to see the advantages of GreenFiltec, enabling the company to expand its presence. GreenFiltec gradually gained a solid foothold and secured more orders from other wafer manufacturers.

GreenFiltec’s second strategic move involves the flexible configuration of filters.

There was a niche memory manufacturer from Taiwan who continuously received complaints from operators about strange odors in their cleanroom. As a result, the plant manager approached GreenFiltec in hopes of resolving the issue. Huang Mingwen recalls that the company set up a small laboratory for A/B testing, similar to TV commercials testing the absorbency of diapers, where the operators conducted a blind test comparing the odor-filtering effectiveness of GreenFiltec’s filters with those from foreign suppliers.

Huang Mingwen revealed that the filters from the foreign suppliers were already sealed, and the odor-removing filter was placed on the top layer, unable to be moved. He said, “We placed the odor-filtering filter on the bottom layer. Interestingly, although some people still complained about the odor, the number of complaints reduced from, for example, 8 people to 4 people. It was because of this that we gained entry.”

The key here lies in GreenFiltec’s replaceable filters, which can be adjusted according to the customer’s needs. In addition, GreenFiltec also provided free assistance to the customer in conducting microcontamination measurements. This successful approach led to a shift in customer preference, gradually making GreenFiltec the primary supplier for the memory manufacturer, with an 80% market share in that plant.

GreenFiltec’s third strategic move involves the recycling and reuse of filters.

The concept of regenerating used filters was an idea that Huang Mingwen realized throughout his career. “In the past, customers would complain to me about not knowing how to handle used filters.” With one-piece filters that include metal frames, customers had to cut them before recycling. However, GreenFiltec’s extraction-style design only requires the filter media to be replaced, eliminating the need to replace the entire frame and reducing waste generation.

Additionally, GreenFiltec utilizes a regeneration process to reuse filter media, reducing waste by over 60%. Any non-recyclable filter media is transformed into refuse-derived fuel (RDF) for biomass energy generation. The resulting bottom ash can be further processed into eco-friendly high-pressure bricks, achieving a 100% zero-waste economy.

Yu Zhifan analyzed that GreenFiltec’s solution aligns with the current trend of ESG (Environmental, Social, and Governance) practices and greatly contributes to the ESG implementation in large semiconductor fabs. This means that GreenFiltec’s differentiated approach not only provides an advantage in competition with foreign filter manufacturers but also generates a lower carbon footprint due to its location in Taiwan.

Increase self-control rate! Filtration can move towards a monthly output of 100,000 pieces, and it will also enter the international market

GreenFiltec’s analysis, according to Yu Zhifan, reveals that the primary source of revenue for GreenFiltec currently comes from filter sales. They also participate in bidding for filter replacement projects in major wafer fabs, allowing them to have first-hand knowledge of filter usage and better understand customer needs. “GreenFiltec may not necessarily make a lot of money from filter sales. The purpose is for GreenFiltec’s staff to be present in the fabs, enabling them to understand customer usage patterns and identify the problems that need to be addressed.”

GreenFiltec is actively increasing its domestic production rate. Yu Zhifan disclosed, “There is significant demand in this area, and the reason why GreenFiltec’s revenue growth has not fully exploded is due to production capacity limitations.”

Currently, GreenFiltec’s monthly production capacity is approximately 60,000 filters. To enhance production capacity, they have strategically invested in a factory for mask filtration layers to cultivate local suppliers. Additionally, GreenFiltec initiated a plan to establish a factory in the Southern Taiwan Science Park in 2021, with production expected to begin this year. The initial plan is to achieve a monthly production of 50,000 filters and gradually expand to a level of over 100,000 filters.

Looking ahead, Huang Mingwen mentioned that they will be sending business managers to overseas locations as customers set up facilities there. Furthermore, GreenFiltec plans to collaborate with local enterprises to explore markets beyond Taiwan and seize the opportunities in the green sector, continuously strengthening their presence.