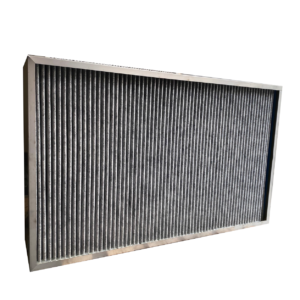

Product introduction

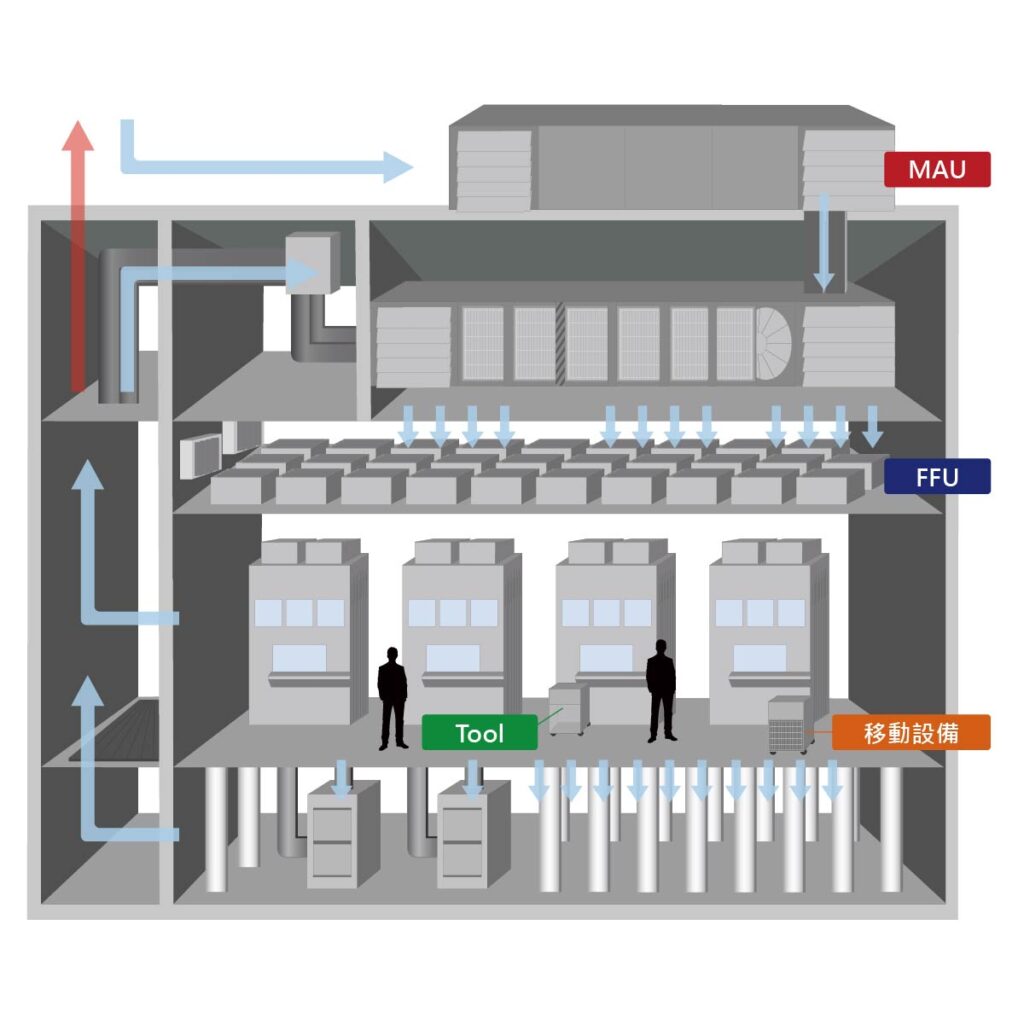

GreenFiltec Ltd.’s “regeneration filter” has “thermal desorption regeneration” technology, which allows the product to be regenerated more than five times, with each regeneration efficiency increasing by at least 80%. Additionally, this technology ensures that the filter plates are completely free of any AMC (Air Molecular Contamination) outgassing. Welcome to contact us to learn more about the product applications, successful cases and optimal purchasing solutions of “Modular Stacked Chemical Filters”.

Product features

- A single chip can be regenerated more than five times

- Green and environmentally friendly products, low carbon footprint

- Low pressure loss, no outgassing, high initial removal efficiency

Product specifications

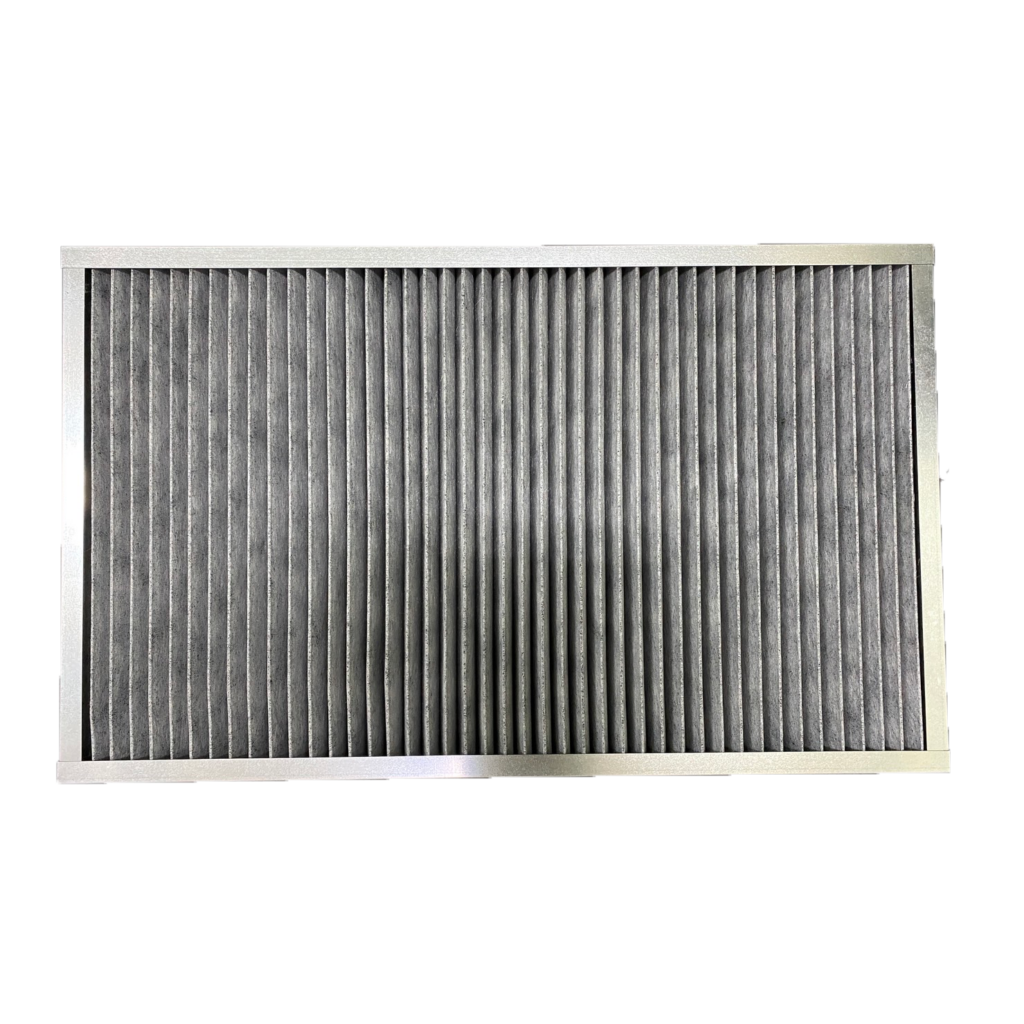

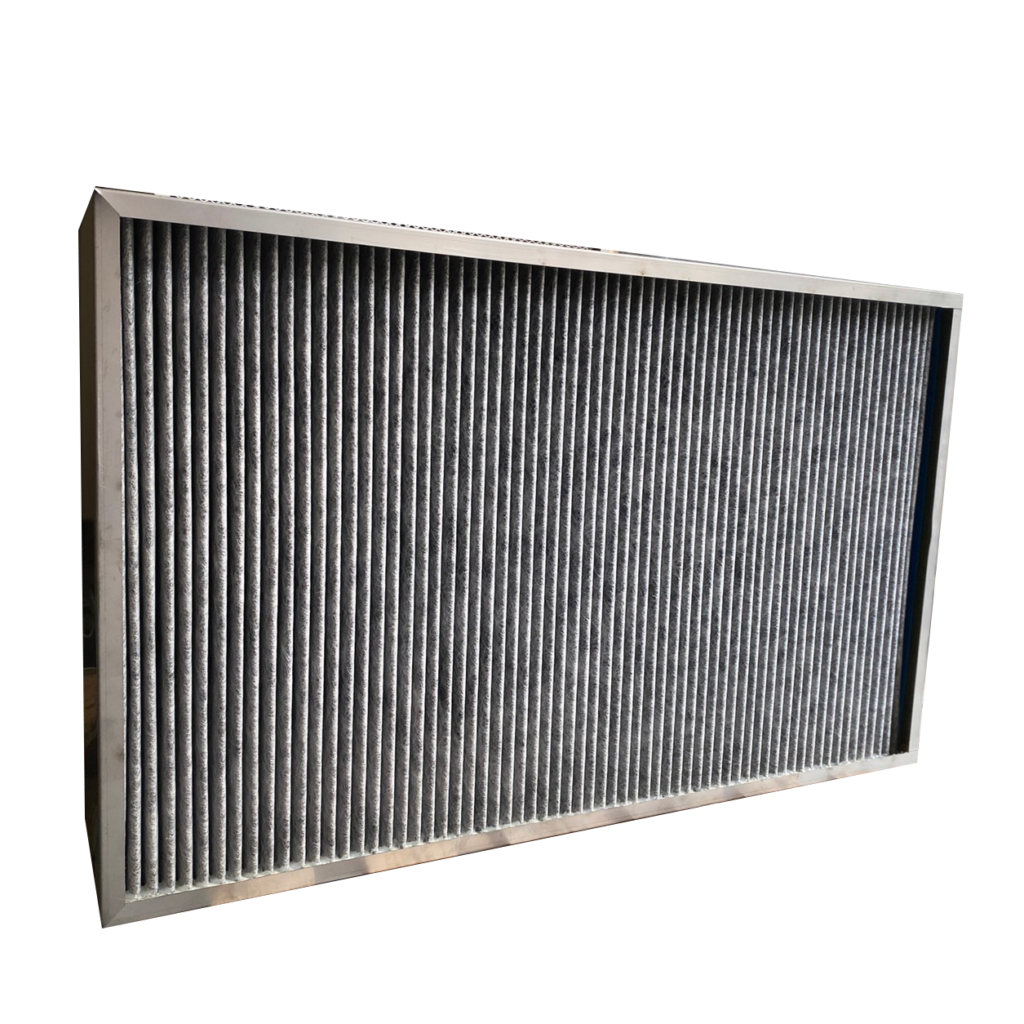

| Filter media | Activated carbon |

| Recommended air volume (CMH) | 500-1000 |

| Pressure loss (Pa) | <35±15% @1000CMH |

| Initial removal efficiency (%) | >90 |

| Weight (Kg) | 6/piece |

| Installation Location | FFU |

| Removable target | Isopropyl alcohol/acetone |

| Frame material (frame) | Aluminum frame |

| Dimensions L×W×H(mm) | 800 × 485 × 63.5 |

FAQ

|

Traditional three-in-one filter |

V.S. |

Environmentally friendly filter |

| A large amount of PU glue is used to join the filter |

Filter Features |

PU free, can save 3~5% cost, No Outgassing |

| Replacing the filter material requires removing the entire set of filters, which is time-consuming and accident-prone | Unique modular design, replaceable single-layer filter material, lightweight and safe | |

| The outer frame cannot be reused | Modular frame is reusable and easy to replace | |

| The frame and filter material cannot be used multiple times, increasing expenditure costs |

Purchase cost |

Reused multiple times, cost can be effectively saved>40% |

| A. The entire set of filters is discarded, generating a huge amount of waste B. Large amounts of waste storage and waste disposal costs |

Waste disposal |

A. The outer frame of the filter material can be reused, reducing waste by >60% B. No large amounts of waste storage and subsequent processing costs |

| You need to purchase a complete set of filters as spare parts |

Spare Storage |

You only need to purchase filter material for spare parts, and the outer frame only needs to be replenished after repeated use |

A plan will be provided based on the concentration in the factory area.

GreenFiltec Ltd. provides 360° services, from on-site inspection and testing, sample analysis, solution development, product production, product sales to customer consultation, etc.

● AMC detection and analysis technology:

We have a professional air filter analysis laboratory team that conducts tests on clean room environmental sampling analysis, filter efficiency, saturation capacity analysis, etc. The test items can be as follows: molecular acid (MA), molecular base (MB), condensate ( MC).

● AMC concentration control:

Based on the information provided by customers and the on-site sampling and analysis results of the Filtration Energy Laboratory team, one-stop services can be provided to assist customers in solving various AMC problems.

● Material outgassing analysis:

Since precision manufacturing processes require good environmental control, the presence of impurities in materials also affects the stability of finished products and application reliability. The specifications for the total release of impurities from materials are particularly stringent. After all, if it contaminates the manufacturing equipment of downstream customers and causes irreversible damage, Filter Energy can provide gas release analysis of various materials for AMC-related projects.

● AMC solution suggestions:

Based on the information provided by customers and the on-site sampling and analysis results of the Filtration Energy Laboratory team, one-stop services can be provided to assist customers in solving various AMC problems.

We have a professional air filter analysis laboratory team that conducts tests on clean room environmental sampling analysis, filter efficiency, saturation capacity analysis, etc. The test items can be as follows: molecular acid (MA), molecular base (MB), condensate ( MC).

● AMC concentration control:

Based on the information provided by customers and the on-site sampling and analysis results of the Filtration Energy Laboratory team, one-stop services can be provided to assist customers in solving various AMC problems.

● Material outgassing analysis:

Since precision manufacturing processes require good environmental control, the presence of impurities in materials also affects the stability of finished products and application reliability. The specifications for the total release of impurities from materials are particularly stringent. After all, if it contaminates the manufacturing equipment of downstream customers and causes irreversible damage, Filter Energy can provide gas release analysis of various materials for AMC-related projects.

● AMC solution suggestions:

Based on the information provided by customers and the on-site sampling and analysis results of the Filtration Energy Laboratory team, one-stop services can be provided to assist customers in solving various AMC problems.