Machine Filter

- Home

- Machine Filter

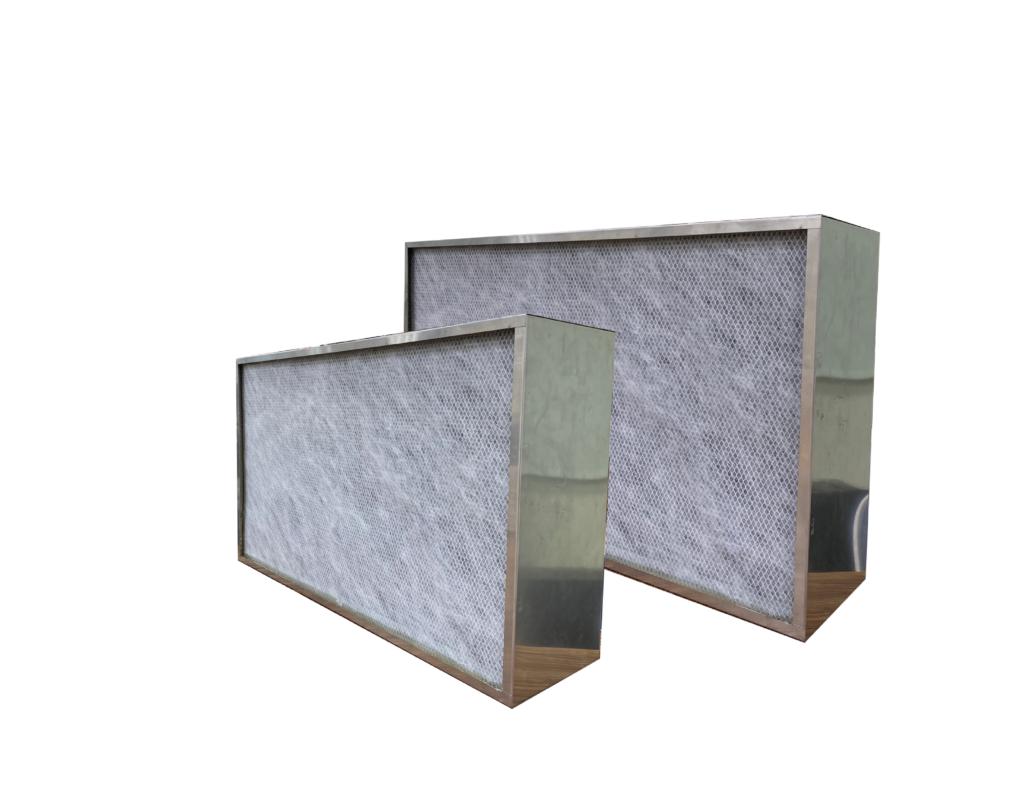

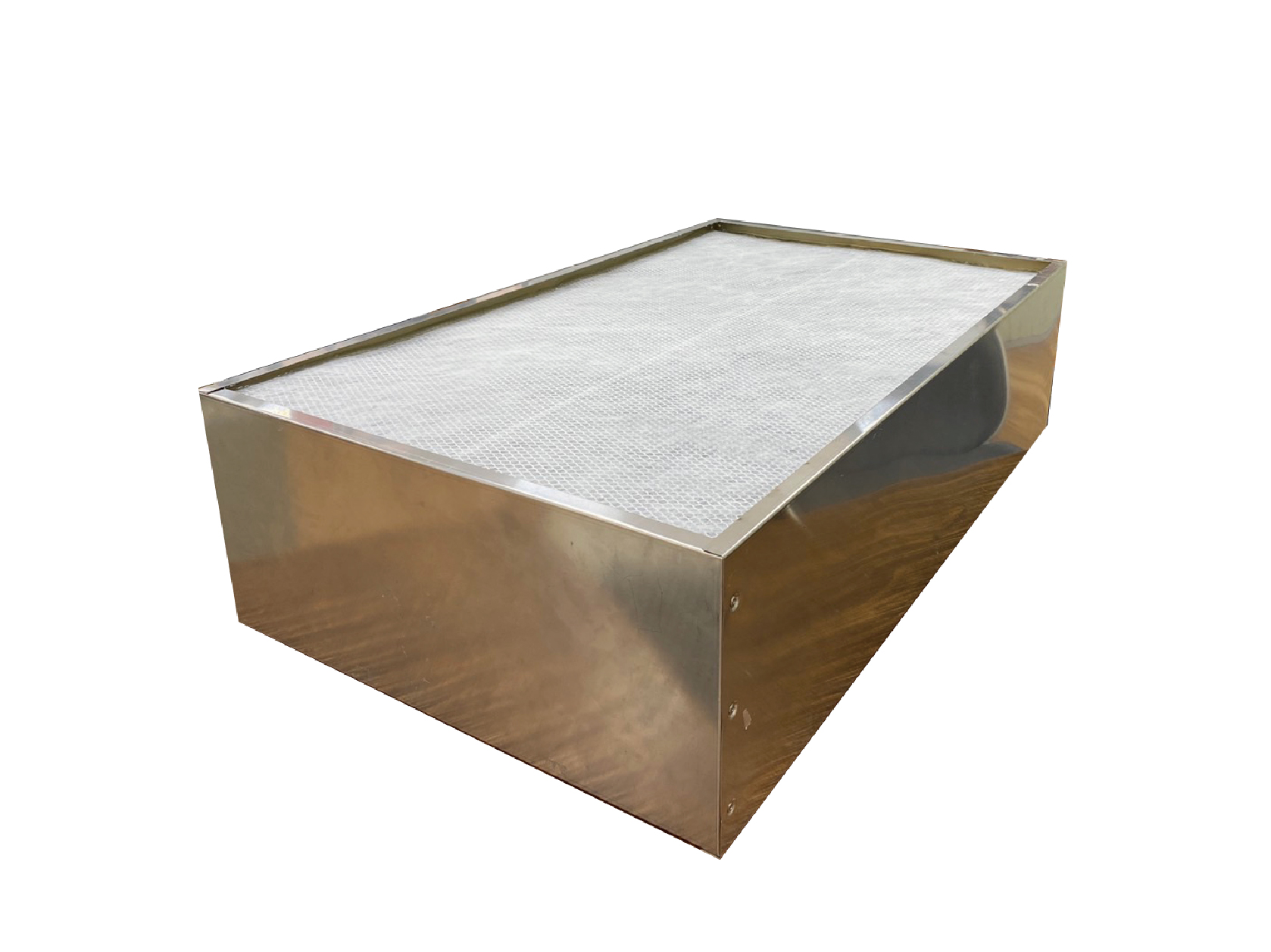

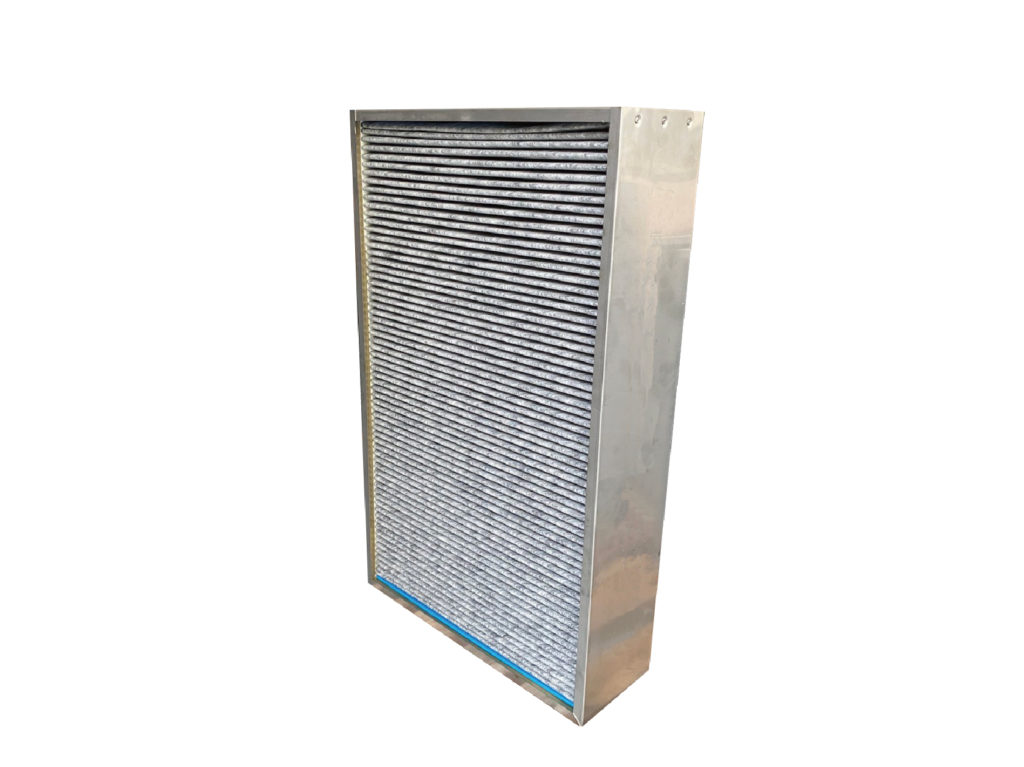

The “machine filter” of the GreenFILTEC has the characteristics of “modularization”, which can be replaced and customized according to customer needs. At the same time, its “drawer type horizontal pull” makes it easy to replace in the factory area with insufficient space above the ceiling.

Machine filter

-Product Appearance-

-Product Appearance-

1. Lightweight design, lighter than competing products, reducing public security factors

2. Low pressure loss design to reduce energy consumption

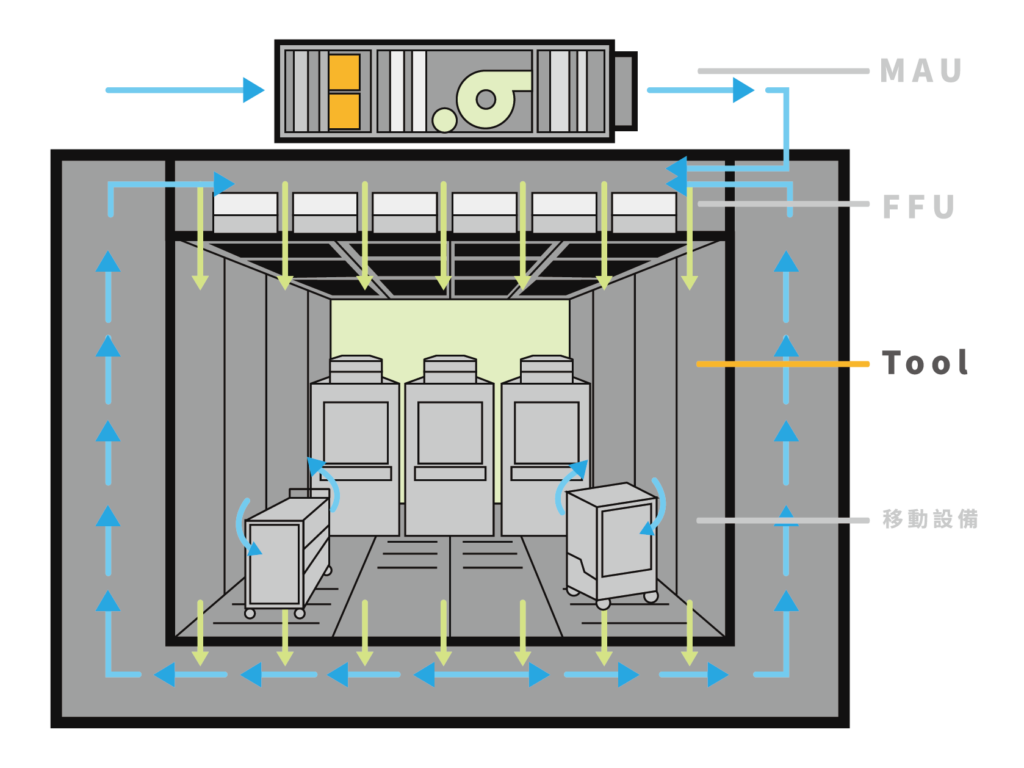

-Installation location-

Installation location : Tool

Three-in-one machine filter

-Product specification-

| Filter Material | Modified Activated Carbon/Ion-exchange Resin/Active Carbon |

| Dimensions of filterL x W x H (mm) | 800 x 485 x 165 (Can be adjusted according to customer needs) |

| Recommended Flow Rate (CMH) | 500 – 1000 |

| Pressure Drop (Pa) | 40±10% / 60±10% |

| Initial Removal Efficiency (%) | SO2>90 NH3>90 VOC>90 |

| Weight (Kg) | 10.5 (whole group) |

| Installation locantio | Tool |

| Filterable Target | MA / MB / MC |

| Frame material | Galvanized iron / SUS |

| Outgassing | No Outgassing |

Machine filter(MA)

-Product specification-

| Filter Material | Ion-exchange Resin |

| Dimensions of filterL x W x H (mm) | 800 x 485 x 150 (whole group) |

| Recommended Flow Rate (CMH) | 500 – 1000 |

| Pressure Drop (Pa) | 35±10% |

| Initial Removal Efficiency (%) | SO2>90 |

| Weight (Kg) | 8 |

| Installation locantio | Tool |

| Filterable Target | MA |

| Frame material | Galvanized iron / SUS |

| Outgassing | No Outgassing |

Machine filter(MC)

-Product specification-

| Filter Material | Active Carbon |

| Dimensions of filterL x W x H (mm) | 800 x 485 x 125 |

| Recommended Flow Rate (CMH) | 500 – 1000 |

| Pressure Drop (Pa) | 15±10% / 35±10% |

| Initial Removal Efficiency (%) | NH3>90 |

| Weight (Kg) | 4 |

| Installation locantio | Tool |

| Filterable Target | MB |

| Frame material | Galvanized iron / SUS |

| Outgassing | No Outgassing |

-FAQ-

Q1 : Comparison of Traditional Filters and Modular Filters

|

Traditional three-in-one filter |

V.S. |

Environmentally friendly filter |

| A large amount of PU glue is used for the joint of the filter screen |

Filter properties |

PU free, can save 3~5% cost, No Outgassing |

| Replacing the filter material requires removing the entire set of filter screens, which is time-consuming and prone to accidents | Unique modular design, replaceable single-layer filter material, light weight and good safety | |

| Frames cannot be reused | Modular frame is reusable and easy to replace | |

| The frame and filter material cannot be used multiple times, which increases the cost of expenditure |

Purchase cost |

Multiple reuse, cost can effectively save >40% |

| A. The entire set of filters is discarded, resulting in a huge amount of waste B. A large number of waste piles and waste disposal costs |

Waste disposal |

A. The outer frame of the filter material can be reused, and the waste reduction is >60% B. There is no large amount of waste stacking and follow-up processing costs |

| Spare parts need to buy a whole set of filters |

Spare parts storage |

Spare parts only need to purchase filter materials, and the outer frame needs to be replenished after repeated use until it is worn out |

Q2 : The average life of the filter?

A2 : According to the concentration of the factory area, a plan will be provided

Q3 : What services are provided?

A3 : Filtration can provide 360° services, from on-site investigation and testing, sample analysis, program development, product production, product sales to customer opinion consultation, etc.

Q4 : Owning the only TAF-certified laboratory in Taiwan, what items can be analyzed?

A4 :

● AMC analysis technology :

With a professional air filter analysis laboratory team, we conduct tests for clean room environmental sampling analysis, filter efficiency, saturation capacity analysis, etc. The testable items are as follows: molecular acid (MA), molecular base (MB), condensate ( MC).

● AMC level control :

According to the information provided by customers and the results of on-site sampling and analysis by the energy filtration laboratory team, we can provide one-stop service to help customers solve various problems of AMC.

● Material outgassing analysis :

As precision manufacturing requires good environmental control, impurities in materials also affect the stability of finished products and application reliability. The specification of the total release amount of material impurities is particularly strict. After all, if the manufacturing equipment on the downstream customer application side is polluted and irreversible damage is caused, Filtration can provide analysis on AMC-related projects for various materials outgassing.

● AMC Tatal Solution :

According to the information provided by customers and the results of on-site sampling and analysis by the energy filtration laboratory team, we can provide one-stop service to help customers solve various problems of AMC.

-Related news-

Previous slide

Next slide

Welcome to contact us to learn more about the product application, successful cases and best procurement matching plan of “Machine Filter”.